Condition Monitoring

Measurement systems for rotating equipment does not need to be expensive to purchase and maintain. We have more than 20 years of experience with instrumentation and data logging systems. We can advise on a number of sensors and transducers to measure displacement, vibration, acoustic emissions, temperatures and ultrasound.

Our specialty lies in developing bespoke measurement software with real-time analysis and minimal post-processing efforts. By incorporating off-the-shelf high-speed data loggers with our multi-purpose software, we aim to provide affordable measurement solutions for every application.

Acoustic Emission

- Acoustic Emission (AE) measurements utilises high frequency sensors that can detect stress waves from surfaces generated from impact, crack growths and even frictional rubbing.

- Frequency bandwidths can be applied to differentiate the sources of AE signals.

- AE sensors can be mounted conveniently on casings of machines.

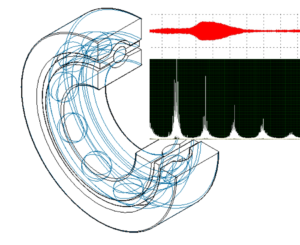

- Correct use of AE technology along with advance signal processing methods can detect onset of rotor rubs in compressors and turbines, including defects in seals, non-contacting bearings and rolling element bearings.

- AE can be used as a standalone tool to accelerate R&D testing or be integrated into a larger system.

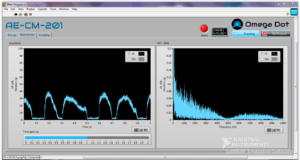

Data Logging Software

- We have the capabilities to develop data logging programs with advance signal processing features, turning a low cost high-speed data logger into powerful real-time measurement systems.

- Features such as filtering, spectrum analysis, statistical analysis, trending and pattern recognition can be incorporated to meet your diagnostic needs.

- We recommend using NI LabVIEW as the preferred platform for software development.

- We also create programs for batch processing of raw data, helping you create analytical reports in matter of minutes.

Papers on Acoustic Emissions

Developing Active Lift Technology to Improve Seal Reliability for High Viscosity Oil Services [PDF]

Ha D N and Meck K-D

11th EDF/Pprime Workshop, “Behaviour of Dynamic Seals in Unexpected Operating Conditions” Futuroscope, September, 2012

Acoustic Emission Study on WC-Co Thermal Sprayed Coatings [PDF]

J.M. Miguel, J.M. Guilemany, B.G. Mellor, Y.M. Xu

Materials Science and Engineering A352 (2003) 55-63. 2003.

Application of Acoustic Emission to Detect Damage Mechanisms of Particulate Filled Thermoset Polymeric Coatings in Four Point Bend Tests [PDF]

Y. Xu and B.G. Mellor

Surface & Coatings Technology 205, 5478–5482. 2011.