Recent Projects

Air Foil Bearings advances Oil-free Turbo Compressors

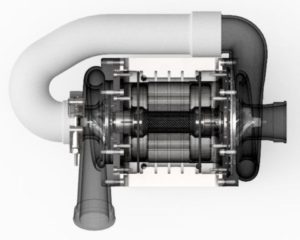

2 Stage Turbo Compressor

- We were commissioned to design, build and deploy a series of large size, up to 75 kW, 2 stage turbo compressors for boosting high powered fuel cell systems.

- The turbo air compressors were built with our advanced air foil bearing and e-motors provided by our partners.

- Our air foil bearings allowed the compressor to be ultra compact, light weight, highly efficient and oil free.

Turbo Air Purifiers - TAP

- The TAP project was funded by Innovate UK with the aim to kill pathogens in the air and prevent transmissions of viruses including COVID-19.

- TAP stands for Turbo Air Purifier. It was developed using our air bearings, turbo fan and germicidal technologies to create the fastest air purifier of its class.

- Tests showed our TAPc achieved a clean air delivery rate that's twice as fast as the leading commercial air purifier of the same size.

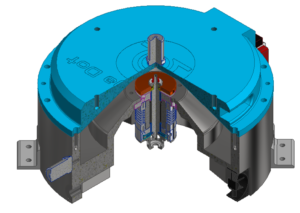

High Speed Material Test Rig

- Employing our air foil bearings and high speed motor technologies, we designed and built a destructive test rig to spin materials beyond the speed of sound until it fractures.

- The test rig can spin materials up to 160,000 rpm in a bomb proof enclosure. It is equipped with sensors and data logging system to determine the exact point of failure.

- This is the first of it kind in the world and it fast tracks the materials test program for our client.

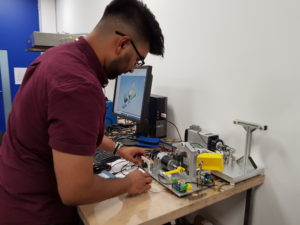

Low-cost Aerodynamic Polymer Bearing

- The project was part funded with Brunel University under the Innovation Voucher and Co-Innovate schemes.

- An self-acting air bearing made out of low friction polymer material was developed and tested to establish airborne capability.

- The work was presented at the IMechE 27th Mission of Tribology seminar and also featured in the 2019 Made in Brunel event at the OXO Tower in London.

STEM Kits for Local Schools

- Project was part funded by the Institution of Engineering and Technology under their EEGS to promote STEM in schools.

- 7 educational kits were designed and made from scratch with the aim to provide engineering experience covering the topics of mechanical design, motors, materials testing, mathematics, electronics, sensors, data logging and science.

- We've reached out to more than 50 students in four schools, providing them with a full day hands-on engineering experience. Overall students feedback was amazing with more than 80% rating. Many of whom learnt engineering is more about team work and problem solving.

Mr Mashida, assistant head teacher of Barnhill community school.

"I don't know how much I can thank you for the amazing big job you have done today working with our Physicists. You have certainly opened their eyes and given them a glimpse of the world of work. Speaking to some of the students I was filled with joy and pride to hear their positive comments about the project. They really appreciate your gesture. The school is proud to be linked to your organisation / institute".

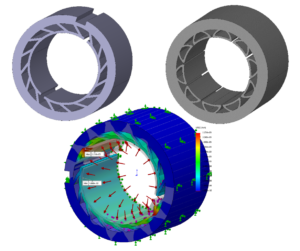

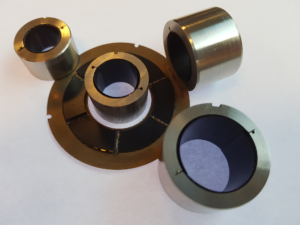

Air Foil Bearings Developments for Turbomachinery

- We design, develop and manufacture air foil bearings for range of high speed and high power density machines.

- We have validated a range of sizes from 17 mm up to 100 mm in shaft diameters and for speeds of up to 170,000 rpm.

- Our air bearings has proven to be extremely energy efficient with minimal air cooling and allows the machines to run completely oil free.

- Our air foil bearings has been accepted in a number of applications within the power generation, automotive and oil & gas industry.

- We have contributed to the development of a range of machines including high-speed motors, turbo compressors/blowers, micro gas turbines and large gas turbines.

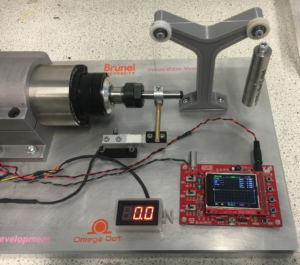

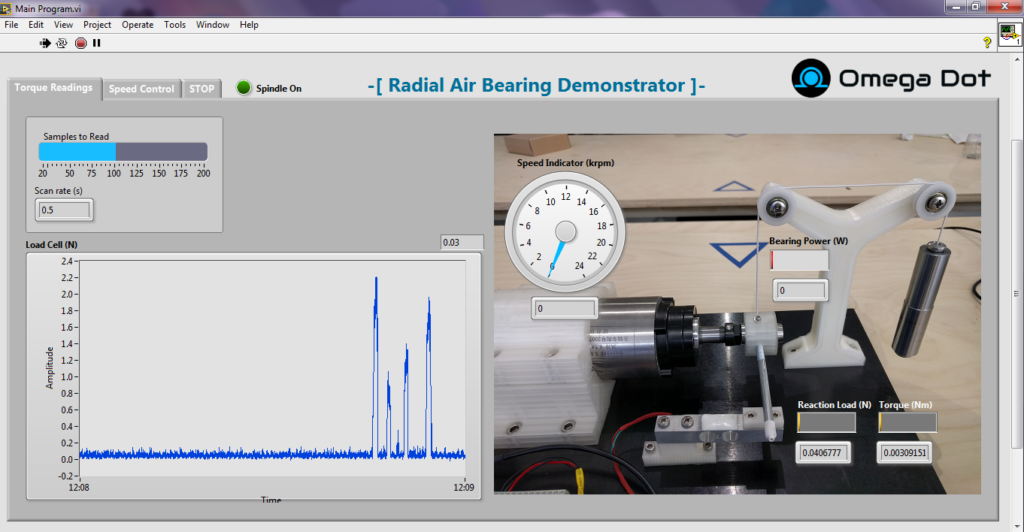

Self-acting Air Bearing Demo

- Test rig built to demonstrate the principles of a self-acting air bearing.

- Torque measurements during the transition of the bearing lifting-off as the shaft accelerates.

- The loaded bearing floats near friction-less at full speed of 24,000 rpm without any cooling.

- As the shaft decelerates the bearing touches down and increase in torque can been seen.

- Air bearing's unique features offers extremely low losses aimed for high speed applications where other bearings would struggle.

- We have the expertise to design, build and test a variation of air bearings to meet your specific needs.

AE-CM-201 - A powerful but low cost condition monitoring system

- Custom built multi-channel condition monitoring system with bespoke software.

- USB powered high speed data logging of up to 200 kHz, 8 channels.

- System can adopt a range of sensors, including acoustic emissions, vibration sensors, tachometers, etc.

- Powerful software provides real-time display of waveforms, frequency spectrum and statistical trending.

- Options for programmable alarms.

- Data saving capability with minimal post processing.

- Both hardware and software can be customised to suit your application.

- Below video demonstrates the system can detect stress waves generated using your finger tips.