Products

All of our products are developed in-house and qualified by many design and testing cycles to ensure it meets exceptional quality and reliability. All of our parts are manufactured to order in UK by our trusted partners. We are certified with ISO 9001: 2015 Quality Management and we have a policy to exceed our client's expectations.

Standard Air Foil Bearings

- Our have established a series of standard air foil bearings for shaft sizes from 12 mm to 40 mm diameters.

- Our air foil bearings are likely to meet your application needs in terms of speeds and loads requirements.

- Our low friction coating have been testing to endure more than 180,000 start-stops cycles independently. We also have a high temperature coating option for applications up to 600 °C.

- Our bump foil bearings has been tested with loads above 500 N without yielding.

- We have to capacity to manufacture low volumes of 5 sets up to 100 sets per month.

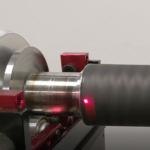

High Speed Motor Modules

- We have developed a series of high speed motor modules with our air foil bearings, ranging from 3 kW to 30 kW.

- The motors can can air cooled or water cooled depending on its size.

- The modules are ideal for fast tracking development projects and can be adopted as alternators for power generation or as drivers for spindles and compressors.

- Our air bearings allows our motor modules to be maintenance-free, vibration-free, low noise and can run continuously with minimal losses.

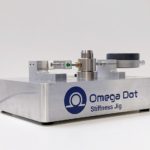

Rigs for Air Bearings

- Besides large scale test rigs, we also produce bench mounted jigs and rigs to support the build, inspection and testing of your air bearings.

- Purpose built rigs are required to check on bearing clearances, bump foil stiffness and lift-off speed validation.

- The rigs are critical to ensuring bearing quality of our air bearings are maintained regardless of the batch size.

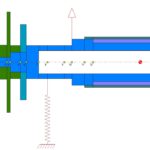

Turbomachinery Services

- High speed turbomachinery requires well designed shaft that needs to have sufficient stiffness to avoid vibration modes.

- We offer design services for turbo shafts together with rotordynamics analysis using DYROBES, to predict the modal frequencies and implement methods to avoid higher order modes.

- We also offer balancing services for rotor components to ensure they within balancing grade of ISO G2.5 or better.